Center hole grinding machine

Center hole grinding is becoming more and more important for precision components. If several diameters have to be ground on a shaft in different work steps, an exact base is required. With the help of our center hole grinding machines (Fischer system, Dottikon), you can grind this base (centers) with a concentricity of 0.001 mm.

The center grinding machine can be configured precisely to your requirements and workpieces

thanks to a wide range of equipment and options.

From manual machines to semi-automatic machines (individual work steps run automatically) to the fully automatic machine, which measures the clamped component with the laser and grinds automatically with the help of the sound sensor - we are sure to find the right center hole grinding machine for you.

For further information of our machines please refer to the flyer.

Download Flyer:

Semi-automatic

Let us know the characteristics of your parts (length and diameter of the largest part, surface finish,...) and we will configure the most suitable machine for you.

With a lot of experience to the optimal result

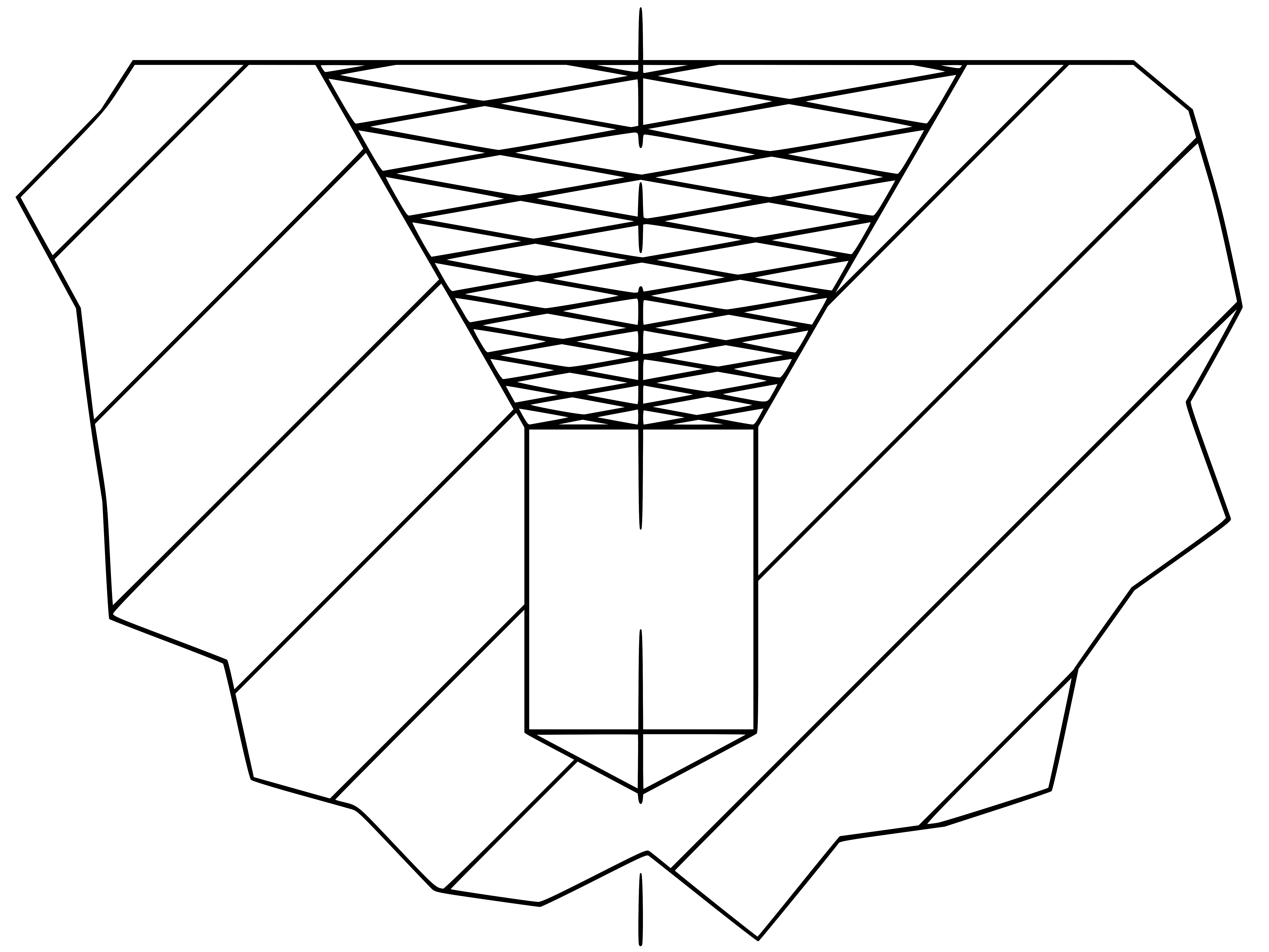

Grinding principle:

1. Rotary move of the grinding wheel

2. Stroke move of the grinding wheel

3. Rotating workpiece

Result:

A cross hatch pattern with oil pockets

that provides optimum oil retention in

the center holes

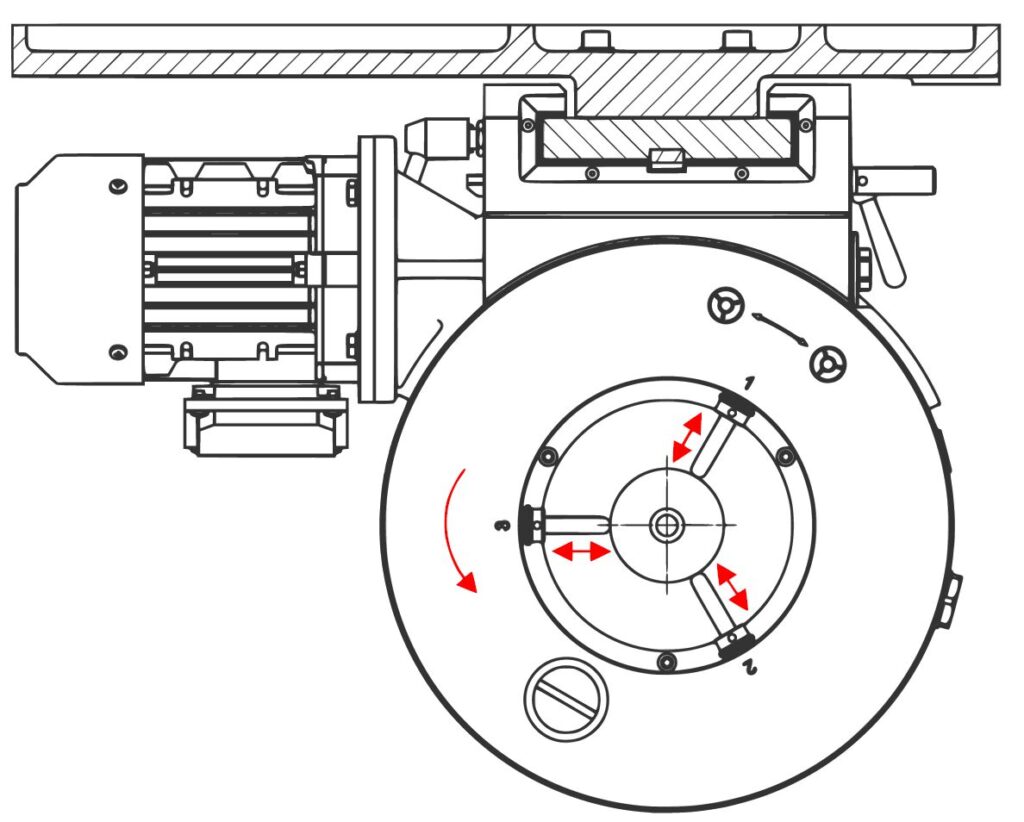

Swivelling grinding head

With the swivelling head the grinding angle can be adjusted between 0° and 90°

Highest precision

The machine achieves a concentricity accuracy of 0.001mm

Clamping of the workpieces in the chuck

With the help of the three adjustable quills even workpieces with an inaccurate surface can be clamped and aligned

Videos

Center hole grinding machine ZSM-M6-1000-SP180-A

with precision 3-jaw chuck and fixed counter tip

Center hole grinding machine ZSM-M6-1000-LM200-A

with steady rest and drive counter tip

For grinding parts with out-of-round or rough clamping diameter. The parts can be straightened with the precision chuck.

For grinding parts with pre-ground clamping diameter.