Press articles in connection with Zeller Automatik AG:

Added value through high-quality retrofit:

Can you make a top product like a grinding machine from Switzerland even better? Yes, you can. What you need for this as a retrofitter is not only expertise in-house but also the right high-performance partners.

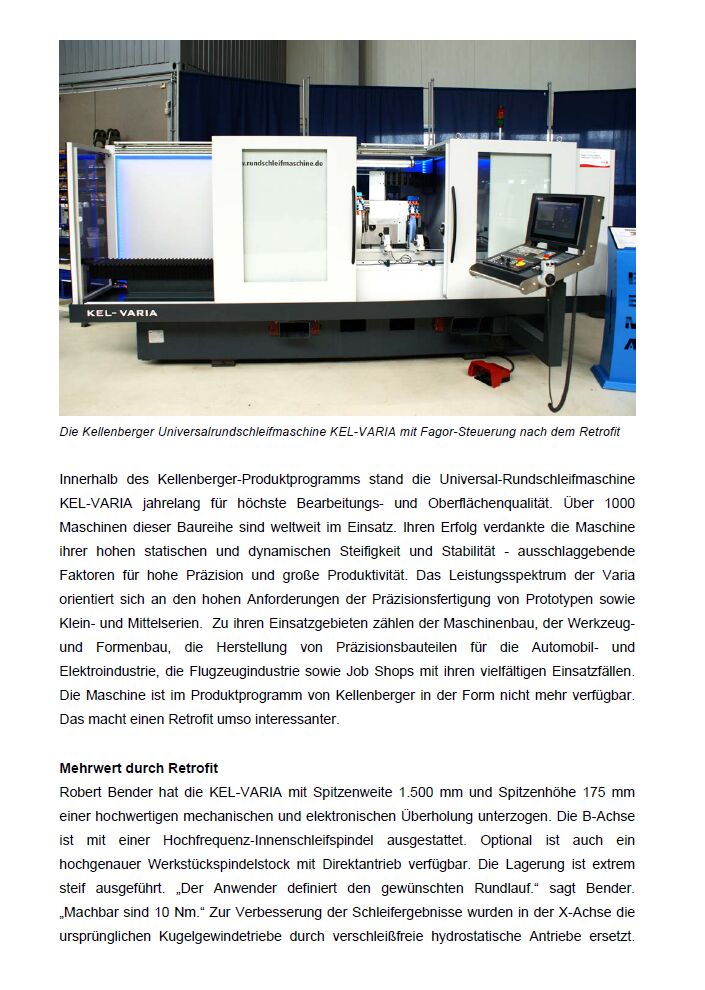

BEMA machine tools from Germany relied on a control system from Fagor Automation and grinding software from Zeller Automatik AG for the retrofit of a Kellenberger grinding machine.

Downloads:

The big SBB project in competition with international companies::

In the case of internationally tendered contracts, Swiss companies are in competition with suppliers from low-wage countries. This example of ZW Hydraulik AG and Zeller Automatik AG shows how, after such a contract has been awarded to Eastern Europe, a substantial part of the added value can nevertheless be brought back to Switzerland. Their executives told their success story to the "Technische Rundschau".

Downloads:

Preserve old treasures:

Every day, contract manufacturers dare the balancing act between calculation and creativity. This is what happened in the case of Louis Zurfluh AG, who relied on new controls, drives and motors from Fagor for the retrofit of their proven BAZ 4S from Reiden. Zeller Automatik AG implemented this step perfectly and brought the machine into the CNC age. An example of how a mechanically flawless machine can be made to shine anew with an electrical retrofit.

Downloads: