We are specialized in the production of single parts and small series. With the precision swivel table PST of our own brand Zamag, the machining of small, complex 5-axis parts is also possible. Our long-term employees guarantee precision and adherence to delivery dates to our customers. Thanks to our wide range of machinery, we achieve a large in-house production depth and thus have a great influence on the price, accuracy and delivery date.

Programming station:

MyXPert VirtualCAM from MySolutions

Our machine park:

| CNC milling: | Machines type: | travel path X-axis: | travel path Y-axis | travel path Z-axis | Spindle speed: |

|---|---|---|---|---|---|

| Manford VL850 (3 axes) | 850mm | 510mm | 510mm | 15000 rpm | |

| Syntak MV-10 (3 axes) | 1000mm | 600mm | 600mm | 10000 rpm | |

| Syntak MV-10 (5 axes) | 150mm | 150mm | 150mm | 10000 rpm | |

| Microcut Eagle (4 axis) | 600mm | 440mm | 550mm | 10000 rpm | |

| Mikron VC-1000 (4 axis) | 1000mm | 660mm | 500mm | 6000 rpm | |

| Fehlmann P18S (3 axis) | 600mm | 300mm | 300mm | 5000 rpm |

| CNC turning: | Machines type: | max. parts-ø: | Peak height: | Peak width: | Spindle speed: |

|---|---|---|---|---|---|

| Ecoca EL-1500 | 300mm | 200mm | 1500mm | 3000 rpm | |

| ZAMAG D102-430 CNC | 100mm | 102mm | 430mm | 5000 rpm | |

| PEP CNC | 100mm | 150mm | 500mm | 5000 rpm |

| Flat grinding: | Machines type: | Grinding length: | Lateral stroke: | Grinding height: | Grinding wheel-ø |

|---|---|---|---|---|---|

| Mägerle F10 | 700mm | 270mm | 425mm | 400mm |

| Cylindrical grinding: | Machines type: | Peak height: | Peak width: | Infeed stroke: | Grinding wheel-ø: |

|---|---|---|---|---|---|

| ZAMAG RSM 102 | 102mm | 200mm | 100mm | 250mm |

| Face grinding: | Machines type: | Peak height: | Pendulum stroke: | Infeed stroke: | Grinding wheel-ø: |

|---|---|---|---|---|---|

| ZAMAG DSM 102-04 | 102mm | 250mm | 100mm | 175mm |

| Center hole grinding: | Machines type: | max. clamping-ø: | max. workpiece length: | Grinding spindle: | Spindle speed: |

|---|---|---|---|---|---|

| ZAMAG ZSM-HF-1000-SP180-A | 180mm | 1000mm | Motor spindle | 60'000 rpm |

3D print

Customize parts? No problem. With our 3D printer we can print your individually element.

We print Onyx. A nylon filled with micro carbon fibers. This gives excellent strength, heat resistance, surface quality and chemical resistance.

For less demanding parts or for prototyping, we also print the commercially available PLA in various colors.

In addition, the following continuous fibers can be cast in:

Fiberglass 5 times stronger than onyx. Best strength-to-cost ratio.

HSHT Fiberglass For high-strength parts at high ambient temperatures.

Kevlar: For particularly robust and impact-resistant parts.

Carbon For applications that require the greatest possible stiffness and strength, but should be featherlight.

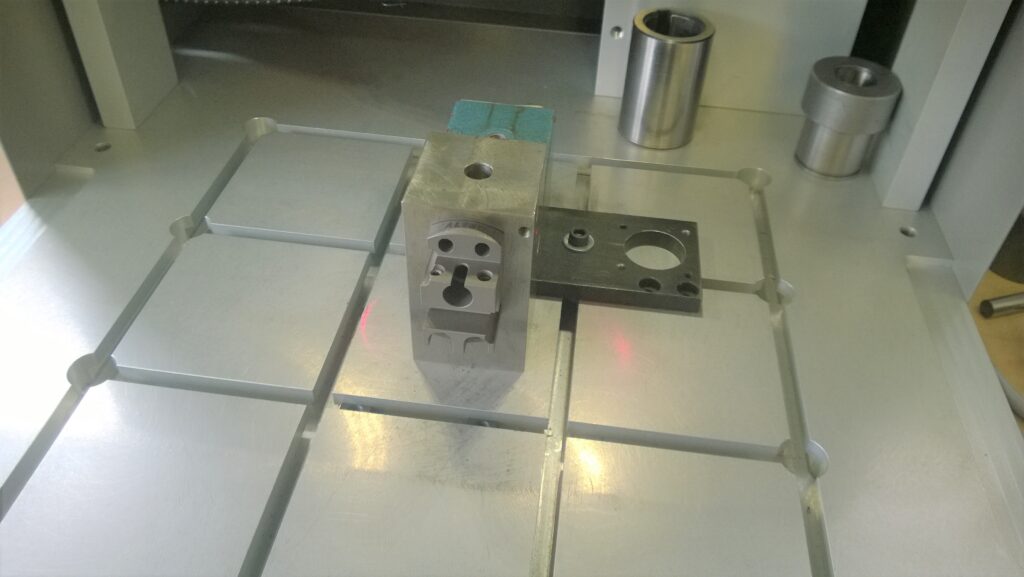

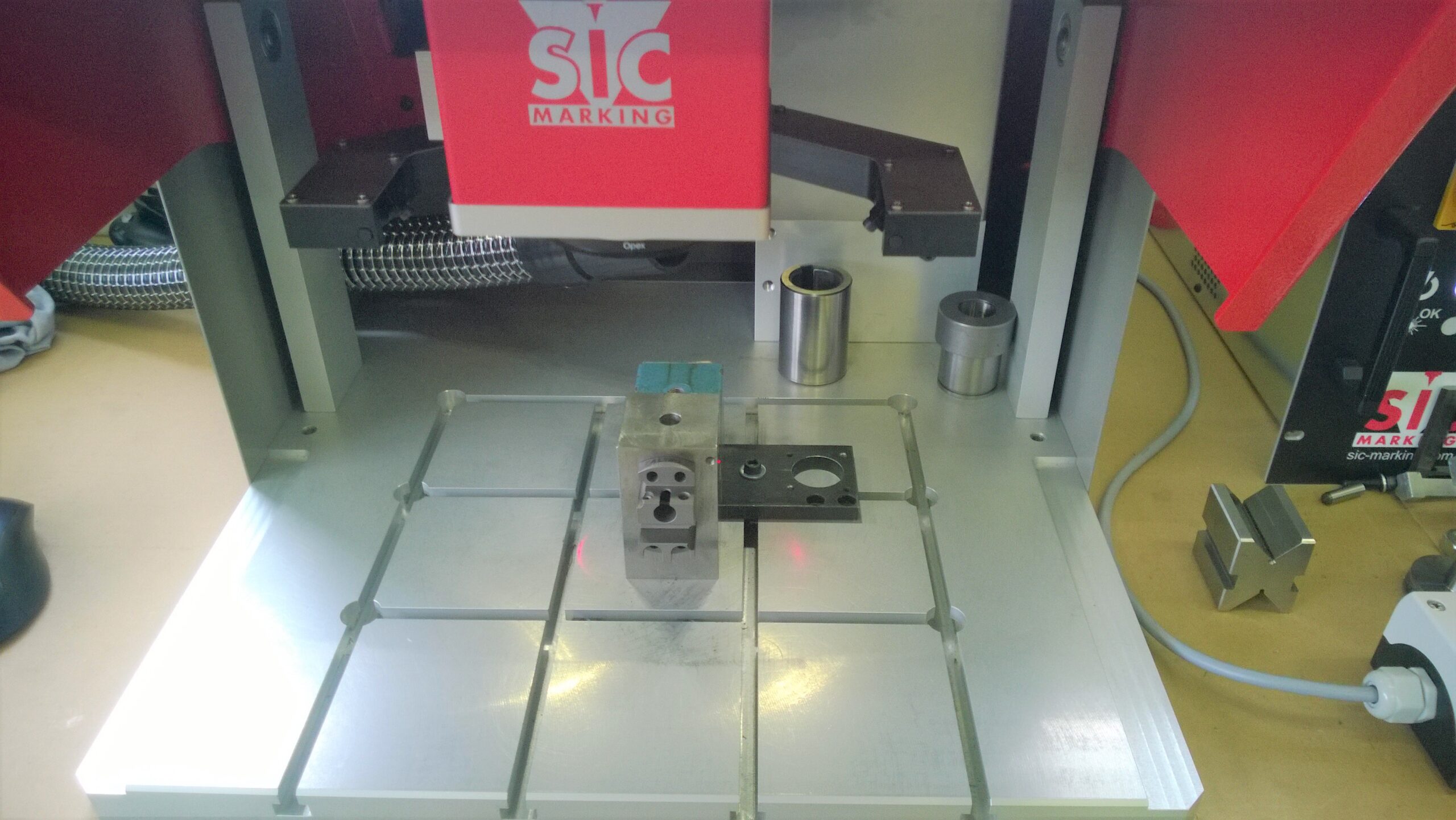

Laser marking

Marking and thus the traceability of parts in the machine industry is becoming increasingly important. In addition, laser marking offers a cost-effective alternative to engraving.

On our own laser marking system we can mark cubic or round components. We can add logos, serial numbers, sequential numbers, deep engraving, bar codes or 3D codes to your parts. Test us.

If you have any questions about laser marking, we will be happy to help you.

| Laser marking: | Machines type: | Editing field: | Clamping area: | Z-height: | Power: |

|---|---|---|---|---|---|

| Laser L-SICL | 100 x 100mm | 450 x 350mm | 150mm | 20W |